Product Series

Solid-Filled Fender

Underwater Airbag Test Report.pdf

Product Details

Solid-filled fender is a protective device used in water facilities such as ships, docks, and offshore platforms. It is primarily used to absorb the impact energy during ship berthing, protecting both the ship and dock structures from damage.

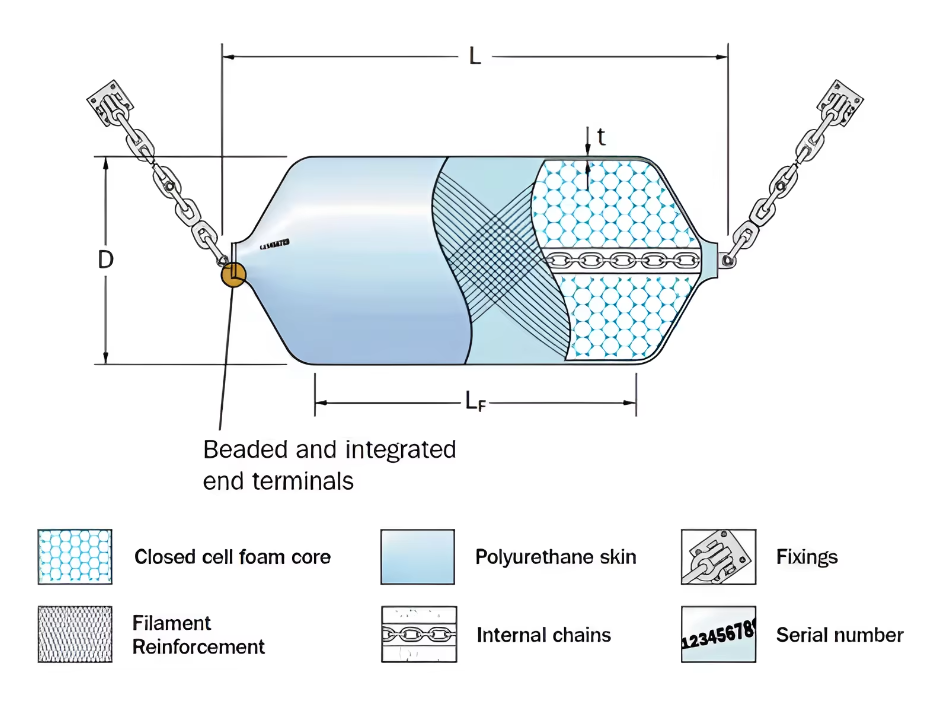

Product Structure

1. Outer Rubber Layer: Made of high-strength, wear-resistant, and corrosion-resistant rubber material, it exhibits good elasticity and impact resistance.

2. Solid Filling Material: Internally filled with high-density materials (such as polyurethane, EVA foam, etc.), it provides stable cushioning and support.

3. Fixing Devices: Including bolts, chains, or anchors, they are used to secure the fender to the dock or ship.

Product Features

1. High Impact Resistance: The solid-filled structure effectively absorbs impact energy during ship berthing, reducing damage to the dock and ship.

2. Strong Durability: Both the outer rubber and inner filling materials have excellent corrosion and wear resistance, suitable for various harsh aquatic environments.

3. Easy Installation: Designed reasonably, it is convenient to install and can flexibly adjust the fixing method according to needs.

4. Low Maintenance Cost: Structurally stable with a long service life and simple routine maintenance.

5. Environmentally Safe: Materials are non-toxic and harmless, complying with environmental protection requirements.

Main Types

1. Cylindrical Fenders: The most common type, suitable for various docks and ships.

2. D-shaped Fenders: With one flat side and one arcuate side, suitable for installation at the edge of docks.

3. Square Fenders: Suitable for special scenarios, such as narrow waters or small ships.

4. Cone-shaped Fenders: Used at the bow or stern of ships, providing better cushioning effects.

Application Scenarios

1. Docks and Ports: Protecting dock structures and reducing impact during ship berthing.

2. Ships: Installed on both sides of the hull to prevent collisions between ships and docks or other ships.

3. Offshore Platforms: For protection of offshore facilities such as oil drilling platforms and wind power platforms.

4. Inland Waterway Channels: Suitable for inland docks, navigation locks, and other aquatic facilities.

Technical Parameters

| Size | Customizable according to customer requirements, with a common diameter range of 200mm to 1500mm |

| Impact Resistance Energy | Depending on the model, impact resistance energy ranges from 50kJ to 2000kJ |

| Operating Temperature | Typically suitable for environments from -40°C to +60°C |

| Color | Generally black, but other colors can be customized according to customer requirements |

Product Specifications

| Size | Compression deflection at 60% | ||

| Diameter/Meter | Length/Meter | Energy Absorption /KJ | Reaction Force /KN |

| 0.5 | 1.0 | 8 | 71 |

| 0.7 | 1.5 | 27 | 161 |

| 1.0 | 1.5 | 49 | 205 |

| 1.0 | 2.0 | 64 | 274 |

| 1.2 | 2.0 | 93 | 337 |

| 1.2 | 2.4 | 110 | 390 |

| 1.35 | 2.5 | 145 | 463 |

| 1.5 | 3.0 | 216 | 624 |

| 1.7 | 3.0 | 273 | 696 |

| 2.0 | 3.5 | 456 | 990 |

| 2.0 | 4.0 | 505 | 1110 |

| 2.2 | 4.5 | 679 | 1396 |

| 2.5 | 4.0 | 781 | 1386 |

| 2.5 | 5.0 | 985 | 1750 |

| 3.0 | 5.0 | 1410 | 2050 |

| 3.0 | 6.0 | 1695 | 2460 |

| 3.3 | 6.5 | 2245 | 2950 |

Structural Diagram

Conclusion

With their excellent performance and wide range of application scenarios, solid-filled fenders have become an ideal choice for protection in aquatic facilities.

Products & Shipping

keyword:

Product Video

Updating, no content displayed at the moment

Related Products

FAQ

Q

What is the minimum order quantity?

A

Q

What payment methods does your company accept?

A

Q

What are your packaging and shipping methods?

A

Q

Can you offer any discounts?

A

Q

Why choose us?

A

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!